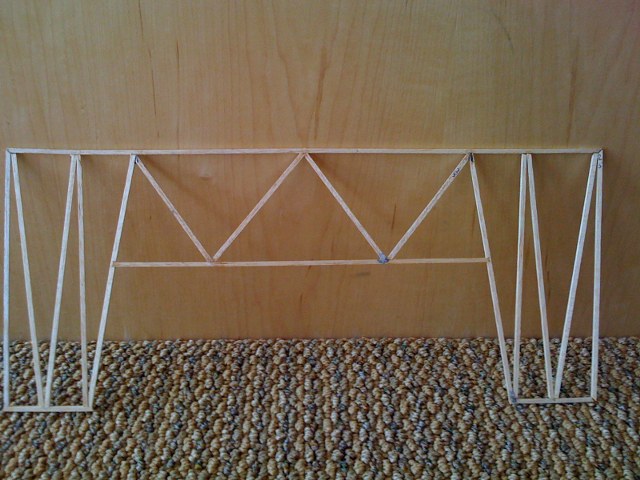

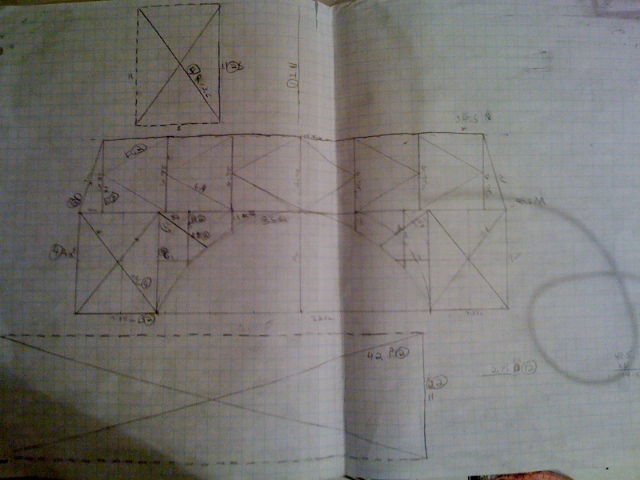

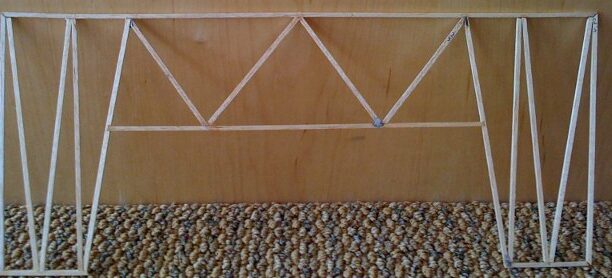

Hello everybody my name is First Timer and I had to make a balsa wood bridge with theses specs: 40.5 cm long, 11-12 cm wide 13-25 cm high, must have a span of 26 cm, peek of the span must be at least 9 cm, and this bridge could weigh no more than 16 grams.

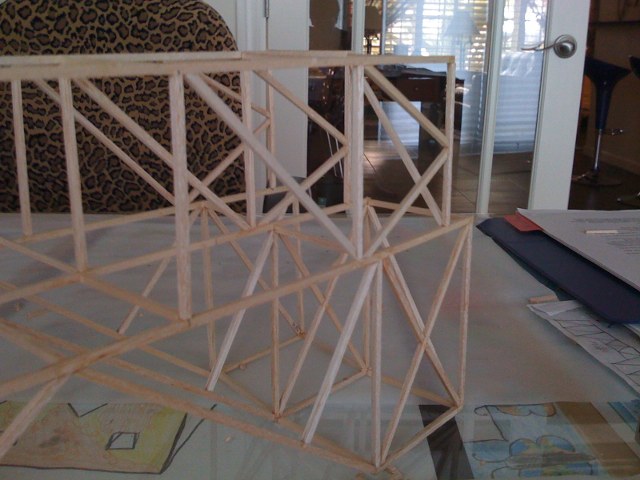

With all the rules in my head and absolutely no idea where to begin, I searched model bridge designs on google. It came up with Garrett’s Bridges and that’s where I started learning everything I know about bridges. First I looked at the trusses and came up with a K-Truss to modify and build a bridge from. My first design was relatively good although I never got around to testing it an engineer said it would hold 35 pounds (maximum). For a first bridge I thought this would be decent but I wanted to win the competition so I modified my K-Truss Arch, and came up with the bridge design pictured. It’s my first bridge so please give me a break. I know it’s rough and sloppy but it took me 3 hours to make.

This bridge weighed 19 grams, so I could not use this for my competition. I plan on reworking the design to make it under weight and hold a higher load. After testing this bridge using the Textbook method (it held 7 textbooks which each weighed 4.5 lbs), I calculated an efficiency at 752. It could be my way of finding efficiency but that stinks so now I have set the bar (very low) and I hope to get an efficiency of 1500 off of this project.

i think that the model bridge needs more support because it looks like it going to fall

Mathieu, you could help out more by explaining why you think the bridge needs more support. Where would you add more?

some joints are not connected to each other and instead connected to a horizontal beam. Balsa woods have very very low bending resistance and that point will fail first before anything else.

Ikianw your right when i weighed it that was the first point to fail.

Also when i attached the second third of the bridge (i built it in 3 stages and combined them) it slipped and got glued to the other piece crookedly but i am definatley going to fix that

Thanks guys again for all the comments about my bridge it will definatley help me when i build more bridges in the future. = D

you need to align upthe upper bridge vertical support to for the span beam with the bottom vertical supports, and once to add more supports such as the compressive tension and zero supporting members. to to give enough support for your bridge slab as well as the oad to be carries

I am moudieMartin from Sudan WES- Yambio from Ezo county southern sudan(Africa)

Lol first timer