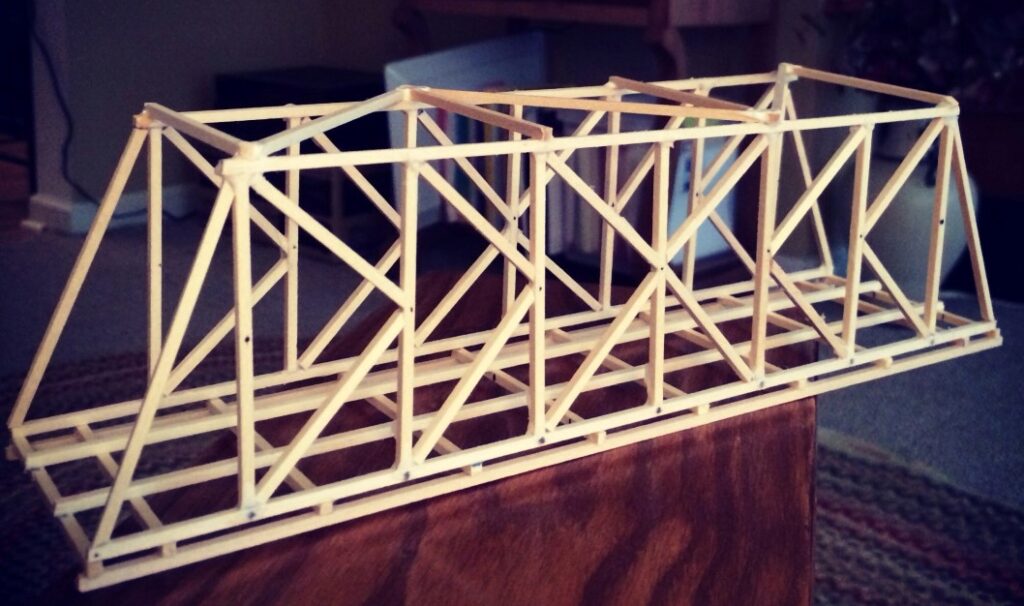

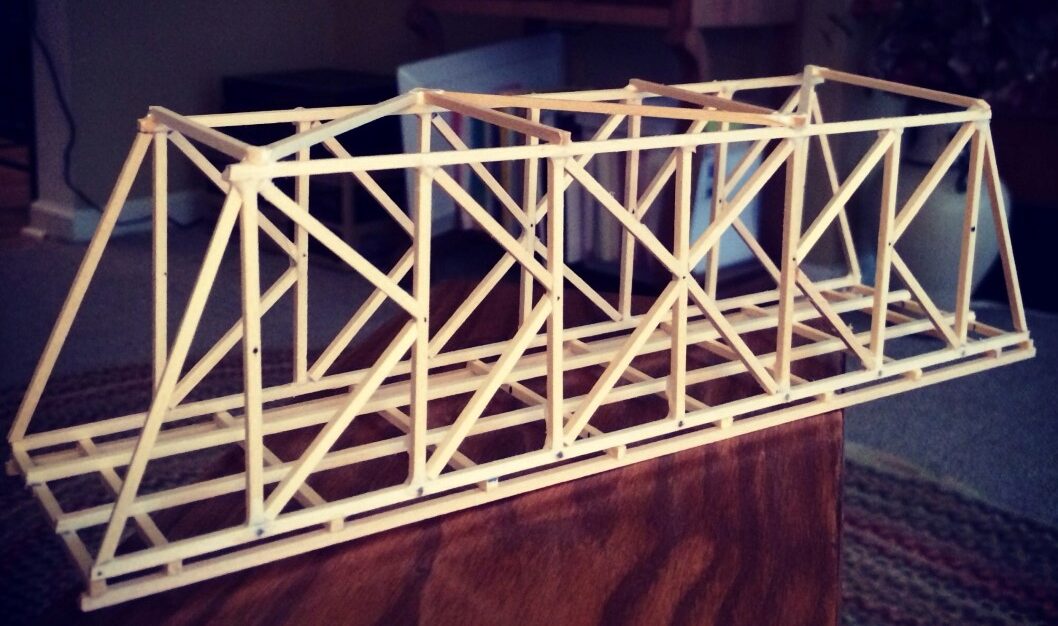

For this balsa wood bridge, I used a ‘K-Truss’ design with seven vertical members and 6 ‘K-Trusses’ per side. The K’s were the most challenging part of the build, because I had to calculate each ones length, and the approximate measure of the angle I had to cut into each one. All in all, the bridge took around 10 hours of work over a three-day weekend (plus glue-drying time, of course).

This website is where I originally found the ‘K-Truss’ design, and it seemed to be the most efficient at distributing forces (though as previously stated, it took FOREVER to build). Also, I added a bit of a spin to the roadbed while keeping the trusses basically the same. Essentially, I made the roadbed double as thick as usual, and added two lengthwise strips to complement the 10 widthwise strips. I will be testing this bridge soon in my physics class, and can only hope it will exceed my expectations. I expect it to hold somewhere between 8-12 pounds, but I wouldn’t be surprised if it held more. Feel free to use this design, just be sure to give credit where it is due. Thank you to this website and the people who comment/add advice to the posts, I am extremely grateful.

-Matt

Thanks for sharing, Matt. Let us know how your bridge does when it is tested.

It was amazing -Matt

How many pounds/kilograms did it hold?

How much did this bridge end up weighing though.

how much weight could the bridge hold? also how much did the bridge weigh?

How does this bridge work?.

Really good how much weight can it hold

Do you have any advice for making the K’s????